Liquidus Tracking System & Software from Planer

- Gradually increases the concentration of DMSO as the temperature decreases and its toxicity decreases

- Uses PT100 sensing equipment

- Stores up to 10 profiles (32 steps per profile)

- Easy to use 3 button controller containing PID engine

- Alarm outputs

- Runs saved to USB (if connected to controller)

- USB port to connect to PC

- Has Planer's Delta T software management option

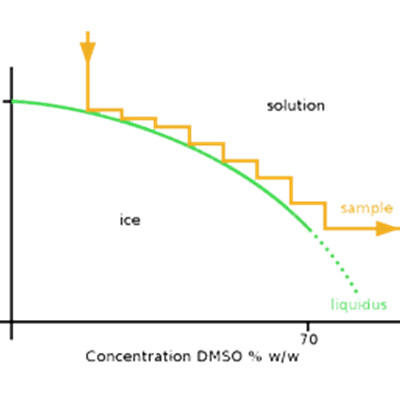

- Liquidus tracking achieves vitirifcation without the fast rates

- Avoids high concentrations of DMSO at the start of the process

- Gradually increases the concentration of DMSO as the temperature decreases and its toxicity decreases

- Cooling rates: 0.01° to 50 °C/min

- Heating rates: 0.01° to 10 °C/min

- Temperature range: +40° to -180 °C

Liquidus tracking is a cryopreservation technique developed to cope with samples that are unsuitable for preservation by conventional means such as controlled-rate freezing and ultra-fast vitrification.

The preservation of biological matter is medically extremely important. Human and animal tissue is stored for research and regenerative medical purposes – bone marrow for cancer treatment, blood products, embryos, skin, bone and cell lines etc. are all frozen for later use. Whilst extra cold deep freezers (similar to domestic ones) can be used, generally the ultra cold of liquid nitrogen at -196°C is required for the greatest storage stability. Current Planer equipment allows some ‘difficult to freeze’ specimens to be cryopreserved with high post-thaw survival of living cells: cartilage is an example of a tissue that cannot currently be preserved with the survival of living cells.

In tissues, for example, extra-cellular ice can form during conventional freezing. In contrast to cell suspensions, this extra-cellular ice can be damaging as it is contained within the system being preserved.

In tissues, for example, extra-cellular ice can form during conventional freezing. In contrast to cell suspensions, this extra-cellular ice can be damaging as it is contained within the system being preserved.

Conventional controlled-rate freezing only tackles the problem of inter-cellular ice, and although conventional vitrification inherently prevents the formation of ice, it typically relies on ultra-fast cooling rates of around 20,000°C/min; these fast rates are unachievable with large samples.

By slowly increasing the concentration of cryoprotectant during the preservation process, the Liquidus Tracker prevents the formation of ice crystals within the samples, allowing vitrification without the necessity for fast cooling rates. This slow vitrification is achieved by increasing the concentration of cryoprotectant while the sample is cooled; the cytotoxicity of the cryoprotectant decreases with temperature and as such higher concentrations can be tolerated at the lower temperatures.

The Liquidus Tracker is a system designed to allow research into the use of liquidus tracking as a means of cryopreserving biological samples that are not suitable for conventional slow-rate freezing or ultra-fast vitrification.

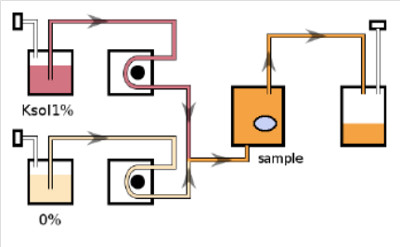

Du al Solution Mode

al Solution Mode

- Two peristaltic pumps feed two solutions to the sample

- First pump feeds a high concentration DMSO solution to the sample container c. 80%

- Second pump feeds a 0% solution

- Pump speeds are adjusted to control the concentration of cryoprotectant surrounding the sample while maintaining a constant flow rate

- Appropriate for small sample containers

- Simple mixing before sample

- Aim to replace volume every minute

- For run from 0 to -70° C at 0.3° C/minute, container volume of Vs uses 233 x Vs of DMSO

- Impractical iv Vs is large

- 320 ml sample container would use 75 L of DMSO

Dual Solution Target Concentration

- Required concentration determined from look-up table

- Table clipped between TL and TU

- Concentration determined from current demand temperature

- Concentration table is %v/v - not %w/w

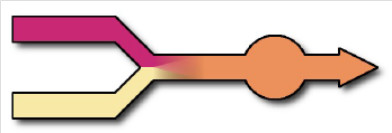

Single Solution Mode

- Two peristaltic pumps used

- First pump feeds a solution at high DMSO concentration into the sample container

- Second pump extracts the solution from the sample container

- Constant volume maintained in the container

- Flow rate into the sample container is adjusted to obtain the correct concentration

- Single solution mode suitable for large sample containers

- Mixing more complex as it needs to be done in the sample container

- Injecting 80% DMSO uses 2.3 x Vs of DMSO to reach concentration of 72%

- 320 ml container uses 736 ml DMSO

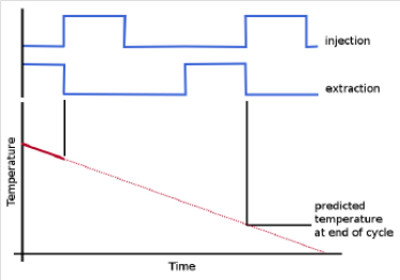

Single Solution Target Concentration

- Dual solution has two pumps running together

- Single solution has two pumps that alternate

- One injects and one extracts

- Pumps do not run at the same time

- Uses same look-up table as dual solution algorithm

- Does not use current demand

- Predicts demand at the end of the cycle

- Prediction simply based on demand at start of cycle and rate at start of cycle

- Does not allow for rate changes mid-cycle

Volume required in Single Solution Mode

- Let Vs = sample container volume

- V = volume introduced

- Ksol = concentration DMSO

- Kt = final target concentration

- V = Vs.In(Ksol/(Ksol = Kt)

Single Solution Pump Timings

- Pumps run in a 3 phase cycle

- Phase 1: Pump #1 injects solution for Tstep seconds

- Phase 2: Both pumps off and solution left to stand for Tstand seconds to ensure mixed

- Phase 3: Pump 2 runs for Tstep seconds to bring volume back to original value

What happens?

- Liquidus Tracking aims to prevent the formation of ice crystals within the sample being preserved by vitrification

- Vitrification normally requires ultra-fast cooling rates 20K°C/min

- Vitrification normally requires small samples to achieve rates

Both systems increase concentration

- The end result is the same

- As the temperature of the sample decreases the concentration of the surrounding cryoprotectant increases

- Dual solution mode continuous

- Single solution runs in small steps

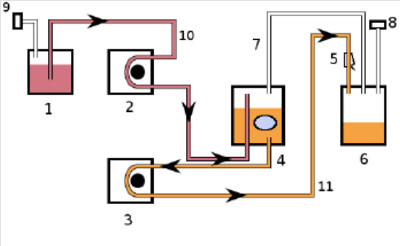

Dual Solution Fluid Path

- DMSO

- Pump 1

- 0%

- Pump 2

- Y-piece

- Sample carrier

- Waste collection

- Filtered exhaust

- Filtered inlet

- Injection line 1

- Injection line 2

Dual Solution Sterile Assembly

- Sample carrier and fluids assembled using aseptic technique

- Completed assembly can then be taken to the liquidus tracker unit

Dual Solution pump connection

- The sample carrier is placed into the chamber

- The two lines are placed into the associated peristaltic pumps

- The system is ready to go

Single Solution Fluid Path

- DMSO

- Pump 1

- Pump 2

- Sample carrier

- Extraction line clamp

- Waste collection

- Pressure relief line

- Filtered exhaust

- Filtered inlet

- Injection line

- Extraction line

Single Solution Sterile Assembly

- Sample carrier and fluids assembled using aseptic technique

- Completed assembly can then be taken to the liquidus tracker unit

Stirrer

- For single solution systems mechanical stirring is required; this is because of the large volumes

- Sample carrier uses a magnetically coupled stirring system to ensure that the solution is thoroughly mixed

- Stirs continuously through all three phases; injection, stand and extraction

- Stirrer oscillates and speed can be adjusted by separate controller

The advantage of the Liquidus Tracking method is that ice is not allowed to form at all. This is achieved by progressively raising the concentration of cryoprotectant as cooling proceeds such that the conditions of the solution that the cells or tissue experience are similar to those that they would experience during conventional cryopreservation but without the formation of any ice.

Cooling and warming rates are flexible, making the method worth trying for some tissues that could not be cooled or warmed rapidly. Cartilage, ova, hepatocytes being possible candidates.

Available Models

|

Product Code

|

Description

|

|

PLLTPKryo360-1.7

|

Liquidus Tracker for Planer Kryo360-1.7 Chamber, Each

|

|

PLLTPKryo560-16

|

Liquidus Tracker for Planer Kryo560-16 Chamber, Each

|

Controller Specification:

|

Model

|

Liquidus Tracker - Controller

|

|

Dimensions

|

24 x 23.5 x 18.5 cm

|

|

Weight

|

2.8 kg

|

|

Display

|

2 x 16 LCD with backlight

|

|

Key pad

|

3 key switches

|

|

Number of stored profiles

|

10

|

|

Steps per Profile

|

32

|

|

Programmable Rates

|

0.01° - 99.9° C per minute (Preliminary)

|

Chamber Specifications

|

Model

|

PLKRYO360-1.7 Chamber

|

PLKRYO560-16 Chamber

|

|

Heating Rates

|

0.01° - 10° C per minute

|

|

Cooling Rates

|

0.01° - 50° C per minute

|

|

Temperature Range

|

+40° to -180° C

|

|

Weight

|

14.4 kg

|

23 kg

|

|

Capacity

|

1.7 L

|

16 L

|

|

Dimensions

|

20 x Ø15 cm

|

32 x 22.6 x 23 cm

|

|

Chamber Access

|

27.1 x 21.7 cm

|

|

Sample Carriers

|

Consult Planer PLC

|

|

Power Requirements

|

115 V, 50/60 Hz, 10 A

|

115 V, 50/60 Hz, 15 A

|

|

Warranty

|

1 Year

|